Air leakage isn't an issue. Based on the enclosures I already have they do a pretty damm good job of keeping the nasty ABS fumes inside.

Just quick math but I should be able to do it. Given that a lot of enclosures can reach 40-50°C without active heating and insulation I guess 70°C passive is realistic when you do 6cm of XPS. I probably will go with an overshoot and cool down the air for the temperature control approach.

Big & bulky isn't an issue as the stock printer is already big and bulky with lots of space for insulation (originally used for the 4 filament spools but they live in a dry box so it is free real estate): The printer already has 60mm extrusion I can fill up with so no additional bulk is added. The bottom plate will be 2cm to keep as much print volume as possible in the z-direction. Maybe I can squeeze also 5cm there with some 3D-scanning and milling pockets.

Even manufacturers of high end printers accept the they will only get ‘good enough’ and that they need to have the heater cycle on and off to keep a steady temperature.

Some heating or cooling is required to keep it stable. Don't matter if you need heating or cooling just something for regulation.

The enclosure for the other printer is slightly more complicated as I am aiming for a 150°C chamber temperature (135°C is required) there which means stainless steel or aluminum inner lining and rockwool insulation that can't be milled to shape like XPS.

Is it really worth it for the small gain in finished product?

Half the fun is pushing limits and seeing what works and what doesn't.

Is your 3D printer insulated? How is the print chamber heated?

How is the build chamber in your 3D-printer heated? Is there any thermal insulation and if how thick is it?

My two cents:

** thermal insulation**

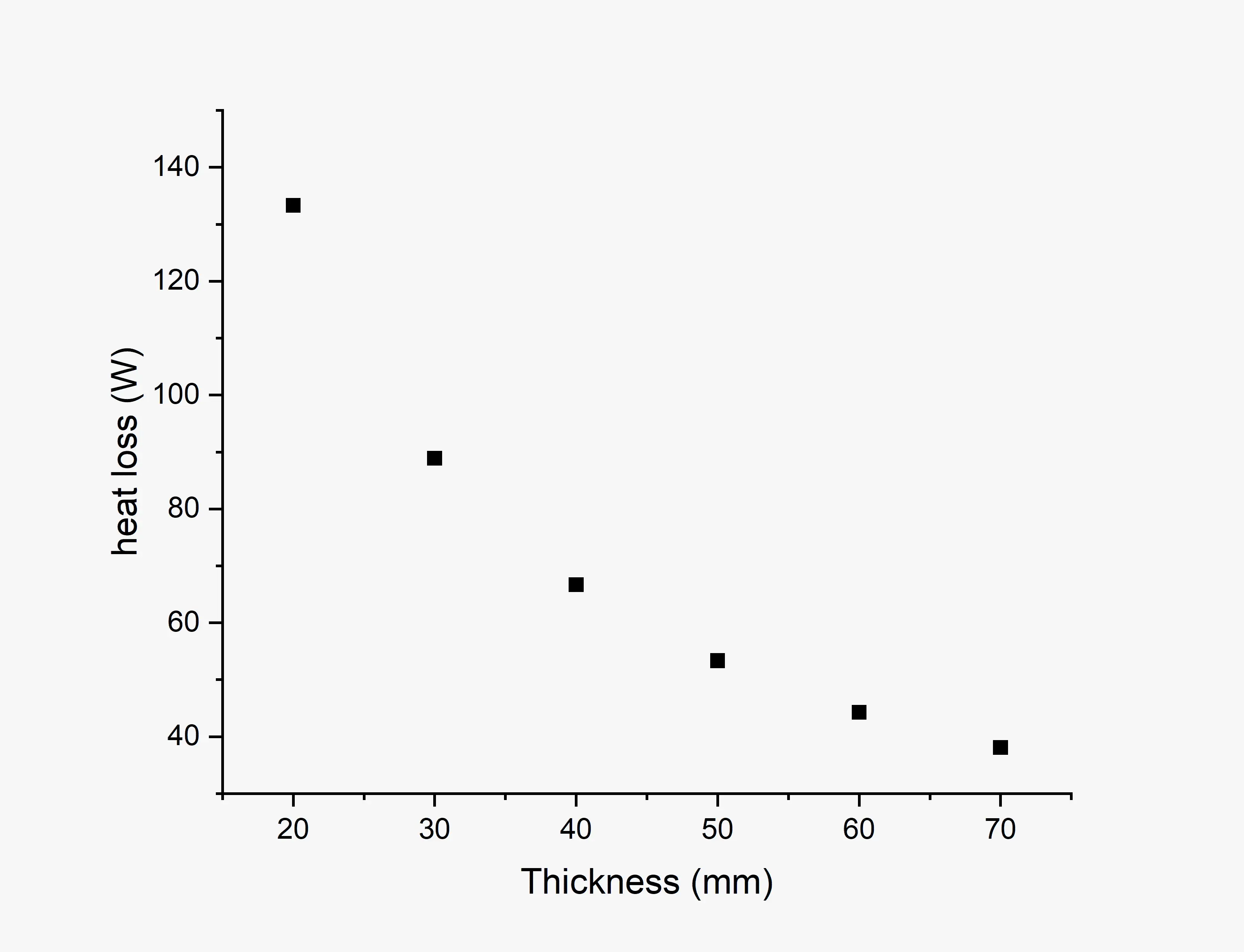

That's the math for a small 300x300mm printer heated to 70°C (for 130°C tripple this number).

With a 6030 aluminium extrusion a 60mm insulation would fit within the walls and bring down the heatloss to approx. 45W. In other words: Once it is heated up the thermal losses are small enough for it to hold the temperature on its own. Reducing the overall power consumption.

heating/temperature control

For cooling and heating: oil<-> air heat exchanger/radiator might be a good solution:

- place one inside the printer

- the other on the outside

- insert a heater in the loop (only when heating is required, for cooling keep it off)

- possible to push past the 100°C liquid temperature.

Add a fan that circulates the air within the chamber to equalize the temperature.

This way the chamber can be heated and cooled without venting any air into the room.

It's fine.

Not great but won't cause issues. Might have a look at the configuration to check that the matching thermocouple type is selected/configured.

I don’t know why Solid Edge doesn’t get more love.

No free hobby license like Autodesk does for fusion360.

There is a free hobby version.

AFAIK at launch they didn't and now the tutorials and people have firmly settled into Fusion360. Unless Autodesk screws up or removes the hobby license it won't change. People are lazy and learning that fusion360 exists is so much easier.

Yeah. PP doesn't stick at all to PEI print beds. Issue is Prusa neither sells HDPE or PP. Neither do they sell printer cable of Printing these materials (build surface).

For Polypropylene: e.g. Eryone is 26€ for 900g (should be more "length"/volume than 1kg of PLA). Fiberlogy is 50€/kg. Not that expensive without the Prusa tax.

For me it feels the polar opposite (ify ou mean with consumer space prebuild 3d-printer it would be a low):

- For the hobby price class, there are better parts than ever to choose from e.g. Orbiter v3 extruder, bacon bed leveling probe, Klipper + Mainsail, good budget linear rails, affordable high thread angle ballscrews, low-cost servos (e.g. JMC motor) and so on.

- projects like the ERCF seeing a big push in popularity

- ToolChanger is on the verge of being mainstream (slicer & firmware support is getting better) [jubilee printer, Voron mods, RatRig vcore mod, Prusa XL, ...)

- significant attention to push beyond classic FDM/molten plastic

None of this will be at FormNext this year as it is a business. It isn't an enthusiast/hobby convention like RMRRF. Maybe in three years, it could be in the first commercial consumer 1machines.

Are you excited about FormNext 2024?

Next week is the FormNext 2024 trade show in FFM. Are you looking forward to visiting it or watching news coverage?

Looking into it I notice that this year there is a noticeable fluctuation. To name one example: Duet3D isn't there this year.

China. That's where you can still get the Cobalt indicator and subsequently on Amazon, Aliexpress or ebay.

The upside is the fantastic color change, which is why some still prefer it and why it is probably still being made.

In Europe there is an alternative blue indicator that is cobalt-free, but it is more of a blue to brown/very dark red colour change, so not great either especially after a few drying cycles.

the granules are blue when dry and turn purple/red when they no longer absorbs humidity.

Don't buy those. Orange gel is the "new" blue.

The reason why the blue gel was phased out decade(s) ago is the CoCl2. Along all of the hazards are H350i and H360F (cancer and reproduction [aka. your plan to have kids might not turn out that great]).

While orange gel doesn't have as good of a color change it is significantly lower risk and shall be used.

Nice to see Piocreat improved this printer. Last year they used V-roller on a $2k+ printer.

Was very interested in it but decided against it as the price didn't matched the hardware.

3D40 at couple hundred bucks? Absolutely not. 3D40 for $50? No. 3D40 for free? Yeah. Just don't expect much out of it.

Go the other way and buy 3mm tubing and see what it does :)

Fair enough bowden has a lot of issues like filament compression (which can't be fixed with tubing) making it difficult to maintain a steady flow when conditions aren't steady (e.g. acceleration and so on).

With larger diameter tubes the issue of filament compressing gets worse. In a nutshell, a larger tube diameter for "rigid" materials somewhat is similar to the effect of a softer filament/material.

With direct drive, I would say it doesn't make a difference.

For bowden there is a benefit.

I also think that direct drive is superior to Bowden setups in nearly every situation. The current generation like the Orbiter v3 is a very light direct-drive extruder.

Don't buy anything you can't afford. Sounds like you already got that part right. :)

If so good 3D-printer are lower cost than ever. Sure you could pick up an used Ender 3 and the like for $50 and put in the elbow grease to learn like it was done in the old days. Alternative is spending $200 on an BambuLab A1 and skip most of the learning curve.

If you can handle frustration than a cheapo used printer could be a good option. Please ask before purchasing as not every $50 printer is a good deal/option and as a newbie you can't distinguish the good from the bad.

Use ASA. PETG will creep.

ASA will creep significantly less. If you have fibre-filled materials they also excel in this regard but are probably overkill here.

PETG will creep even at temperatures below 80°C and the higher the temperature is the faster the process is: https://en.wikipedia.org/wiki/Creep_(deformation)

I have a small collection of parts that all experienced creep (as a showcase). Structurally they where all fine in simulation and practice. Over time they all failed due this deformation.

For production parts look at other materials. Nylon might still be within the range of your 3D-printer.

For attaching: If you can't clamp then look at gluing it in place. If you need it detachable maybe drill a hole in the shaft and use a R-clip.

You can also tap and die the shaft on top. Make sure to use a left or right-handed thread depending on the rotation/load (thread is so that the rotation/force isn't unscrewing it).

What is the plastic of your choice?

PLA, PETG, ... behave like a very slowly flowing liquid as such the print will deform/expand (creep).

Interesting 3D printer design.

Using 3 linear rails to mount the bed. I suppose each linear carriage is one "corner"/point and all three of them to define a plane without overconstraining the buildplate but you keep all of the rigidity of the linear rails?

The issue I see is that the three linear rails in one plane are overconstrained so it is still is a pain to setup (especially on an ender 3 like frame construction).

What is the reasoning for using two motors instead of one powerful in the middle?

Heat set inserts are an interesting topic. You don't need them if the screw is only installed once. Sure enough you can drive a metric screw into a 3D-prind and form/cut the threads but better are self tapping plastic screws. For nut vs. insert: It depends. if you can get away with a square nut (e.g. DIN 557 | don't use hex nuts like DIN934) they are quicker to install. Make the cutout slightly undersized so the nut is fixed/wont move when the screw is installed.

If you use inserts consider the flange type to get a very nice aesthetic: e.g. https://de.aliexpress.com/item/1005006135129074.html

Removable plastic rivts are also a great fastening option. Push pins with integrated spring are equally briliant. Parts with snap fits are awsome but very diffuclt to design as the tab needs to flexible to be pushed in place but still strong enough to not break (layer adhesion).

Warping is indeed a big selling point for these materials. Major selling point/driving force I belive is still the esthetics of them as they provide a surface finish which can be sold (without post processing) without looking like a FDM 3D-print. Less warping, improved properties is more of a nice to have for most applications.

don’t seem to be, at least at the hobbyist level

This can be sad about a dozens of constructions. ISO1234 /DIN91/GB91-2000 splints are everywhere in the industry but nobody in the hobby space knows about them.

It’s pretty common to see cheap bearings in 3d printed parts, actually mildly interesting to me that bushings don’t seem to be

For bushing vs. bearing: It always depends on the application and industry.

. Do wonder though about the wear of 3d printed bushings, surfaces won’t be smooth,

Talked a while ago to somebody that run studies on FDM printed bushings. The verdict was that print orientation/layer adhesion was a limiting factor with their setup.

Should I distill IPA (isopropanol alcohol) at home for 3D-printing?

TL;DR No.

What you should do:

- buy fresh IPA. It is approx. $5/L. As such a 2L washing bin is approx. $10 + 10L waste disposal. In the broader picture of total costs and production value, this is manageable (resin cost, machine depreciation, PPE/gloves, ...)!

- use two or three stages of washing

- fill the washing containers with as little as necessary to get it done

- periodically expose the liquid to sunlight and let the particles settle down. Separate the "clean" liquid from the sump (you might add special chemicals to speed up this process).

- if the first stage needs replacement: 1.) responsible disposal of the liquid in compliance with local regulation 2.) move the liquids around: (the third stage is the new fresh liquid, the second is the prior third stage and the second washing station is now the first "dirty" stage).

- check for alternative chemicals that can be used with your particular resin

If you use water-washable resin: IT IS A DANGEROUS LIQUID! Dispose of dirty water responsibly as chemical waste.

Long answer:

To answer that, let's first look at what isopropanol (IPA) is: Its formal name is propan-2-ol and its CAS number is 67-63-0.

As a starting point, check a database like GESTIS (German) and NOT wikipedia: https://gestis.dguv.de/data?name=011190

At the top of the page we see that it has GHS-02 and GHS-07 warning labels. Looking further, it is a colourless liquid with a flash point of 12°C and an ignition point of 425°C. The explosive range is 2-13.4% vol. The signal word is DANGER.

Scrolling down:

> The substance forms explosive peroxides.

What does this mean?

There is no mechanism mentioned, but generally, if you expose these chemicals to sunlight they will react over time to form a peroxide, which is much more reactive and can explode at high concentrations (there are exceptions to this rule, but most of them go boom).

This means for distillation:

- avoid "old" IPA if possible

- check for peroxides (if necessary, treat the peroxides before distillation)

- don't distill dry (leave some liquid in the sump to avoid high concentrations of peroxides)

As I believe this shouldn't be done at home I won't tell you how it can be safely done (if this isn't enough to deter you: read scientific literature/books describing how it shall be done).

Instead, focus further on what advice is out there on the internet/YouTube:

- A water distiller is made for water and water isn't flammable and doesn't form explosive atmospheres. In other words they are unsafe for Isopropanol or Ethanol.

- Do you think a 2kg fire extinguisher is enough? Are you truly capable of thinking rationally when there is a fire or would you panic like most people?

- Don't even consider doing it indoors or in a garage.

- Don't work with large volumes. In a laboratory with proper fumehoods and equipment, there might be limits like 500mL batch sizes.

- If somebody isn't wearing eye protection or heating large amounts of liquid without stirring question his qualification to talk about this topic. Being an influencer or posting online, like this post, doesn't require any formal qualification as such even the big YouTubers/influencers post horrendous content that is dangerous or misleading.

Prusa MK4s launch (TLDR)

Prusa video: https://www.youtube.com/watch?v=VO2MaQrUcqE

TL;DR For those who don't want to watch 10-minute video:

-

MK4 to MK4s uprade kit: 109€ + shipping (MK4 customer will receive a voucher (except shipping cost))

-

Larger cooling fan

-

Improved cooling duct

-

high flow nozzle

-

NFC for app

-

some parts upgraded from PETG to PC-CF

-

MK4s still ship without an accelerometer. Prusa claims this isn't needed.

-

No camera.

-

No upgrades for the Prusa XL in the near future!!!!

other stuff:

-

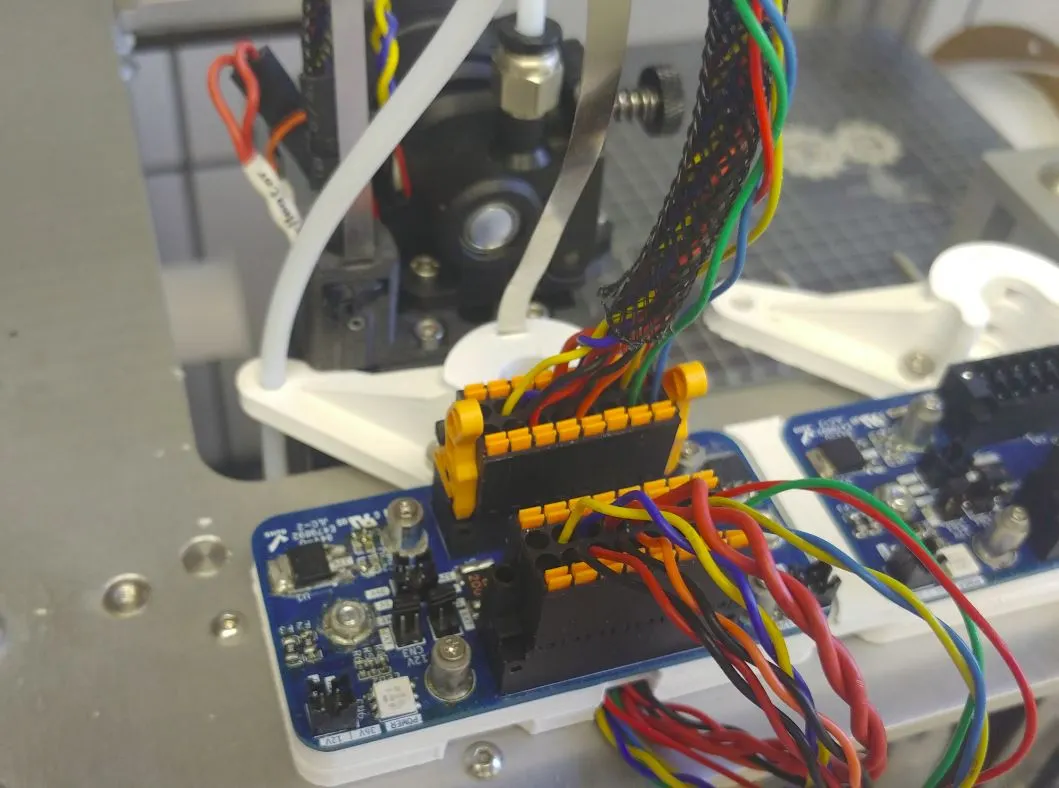

accelerometer board

-

GPIO board

Personal Opinion:

This should have been the MK4 to begin with and shows once more how blindsided Prusa was. BambuLab put so much pressure on them that they had to publish the MK4 in the state it is.

Regrading the Prusa XL the trouble continues. This launch/printer has been riddled by issues after issue and now the statement that the improved part cooling won't make it to the XL in the near future.... My guess it that they screwed up with the XL and didn't consider large toolheads at the design stage favoring a 5 toolhead design over a 4 head option and now run into the same issue I do with the E3D (it can fit those 6023 fans but not like they mount it on the MK4s). For example, with my E3D tool changer, a tool must fit within a 85mm(w) x 60mm(depth) surface area.

For the technical side?

The larger fan is great as it allows to use fans with decent pressure at the target airflow with a low noise. Those 4020 found on most printers aren't a great choice.

High flow nozzle? Yeah ... nothing groundbreaking or new.

NFC and app? A year ago was prusa connect at best a beta. Maybe a an alpha as I would need to restart the printer twice a day because it froze/crash. The value here depends on if they meanwhile fixed it or it is still a joke.

GPIO board? Depends. Might be held back by the firmware as those things require macros to be useful and Prusa firmware never was build around this idea. Still nice to see them publishing this.

Should every printer have a easy to disconnect toolhead?

Quick upgrade for easy to plug and unplug end effectors/toolheads. Activity/status LED are also moved from the back of the printer to the top and some more voltage regulation to provide additional voltage rails.

While a nice connector adds significant cost it is also a big value add for certain 3D-printer. I think more manefacturer should consider tiny details like this when designing their product.

Strain relief isn't installed on this tool for reasons ...

Let's talk about Prusa Printables contests. It might need some fixing.

Currently, Prusa is doing a terrible job with the Printables competition, to the point where they could be in legal trouble if someone were to push for it.

A few examples to prove this statement (5th is in my opinion the worst):

-

insect hotel -> canceled due to security concerns. Great work, but why not look into it before you start and provide a design guideline? https://www.printables.com/contest/436-insect-hotels

-

Bathtub toys -> Mentioned explicitly: "Safety is our top priority, so make sure your creations are child-friendly, [...]". As these are bath toys, one might assume that they mean safety standards for young children. https://www.printables.com/contest/428-bathtub-toys

Great. Safety is a top priority. So let's see how they moderate it. They haven't... If you scroll through the valid submissions, there are dozens that aren't safe for children. Prusa is EU, so I would expect them to be familiar with the basic EU regulations for children's toys when they say we want safety first. There are very strict test requirements that a toy has to meet. The simplest one is a bin/cylinder that a part cannot fit into (choking hazard). Does every design meet this very basic design rule? No. Next comes impact resistance and the like. Does the design meet these requirements? no.

You could say that it's just not feasible to review every submission, so let's take a look at the winning entries that they definitely looked at: Rubber Band Submarine. I'm not a toy designer, but I'm pretty sure that an exposed rubber band is not safe for small children, who are the target audience for bath toys.

-

fish tank tweaks: Recommending PLA for prints that are permanently submerged ("It is usually recommended to use ABS or specific food-safe PLA..."). Seriously???? These days they are PLA under these conditions is rubbish within a year. Discoloration and expansion destroy some PLA blends/filaments.

-

soldering aid: Seeing this design as a winning soldering aid raises serious questions as to whether the person involved has any practical experience in assembling electronics. Placing a PCB 2cm in the air with sharp objects around the mounting holes is the opposite of ergonomic and comfortable SMD soldering: https://www.printables.com/model/740818-parametric-stackable-pcb-standoffs-m2-m14-holes

****5. This contest had questionable practices and here's where things get wild. Now we're not just talking about knowledge gaps, we're talking about breaking your own rules, which could be a legal problem. One of the contest rules states: "A valid entry may change its slope, altitude or distance." Simple. Right? Not for Prusa: https://www.printables.com/model/837104-the-rig-r11-diy-helper-stand-for-testing-electroni

This is a winning entry that can't do any of those things, and would probably qualify as a generic holder (also not a valid entry).

Another winning entry that wouldn't be a valid entry if Prusa followed the contest rules: "Skip the organisers: We love a tidy workplace, but today we're focusing on ergonomic improvements": https://www.printables.com/model/808502-heat-insert-press

Want a third from the same competition? Here it is: https://www.printables.com/model/808502-heat-insert-press "Specific adaptability: Designs must provide flexibility in the user's interaction with the tool or aid (height, tilt, distance or orientation adjustments). Simply accommodating different sizes of objects doesn't quite fit the bill".

To recapitulate, Prusa broke the rules not once, not twice, but three times within this competition (which, being EU, has some legal requirements on how you can and can't run competitions) by awarding prizes with monetary value and talking them away from other competitions that followed the rules.

There is more wrong with how this was organized/done, but I think this is damning enough. Never assume evil, so I would kindly call it Prusa being utterly incompetent.****

- The current XPR challenge. Design a part for a robotics kit. Sounds exciting. First bummer, it's $115 + tax, but that wouldn't be noteworthy enough to write this:

6.1 To design for it a.) either buy it (providing a $35 discount if you do so) or b.) try to work with whatever this is: https://www.printables.com/model/576581-xrp-robot-part-of-the-experiential-consortia/files the picture shows a complete model with PCB and sensors (some connectors and wiring are missing) but would be workable. What do they actually deliver? The frame with no electronics or components. Good luck working with that.

6.2 While this may or may not go in the direction of predatory, there is more: "Photo quality - Well lit, in focus and clear photos will help showcase your work and help us choose the best designs." Quick questions: How do I take good and compelling photos without the $115 robot kit? | Prusa: "This also means that you don't need to own a 3D printer to enter". Question: "How do you make photos without a 3D print to show of? the wording is very clear that they mean photos and not computer 3d-Render. Just by looking at these two aspects, this thing has a $115 + tax ticket to improve the "chance" of winning.

6.3 Moral issues: This work is unpaid to begin with. Does Prusa really expect people to spend tens of manhours working on a good design, printing it, taking pictures, writing instructions and text, when they have absolutely no use for it themselves, since this kit has probably only been sold a handful of times to end users. There is only a small chance of wining something (remember exhibit 5 where they didn't even follow their own rules)?

Last but not least: "Popularity – Share your model to increase its popularity, and prove that users appreciate such a model." This is fairly common for some events and I always dislike it as this asking for free advertisement. Prusa at least limits it to the model itself while others use a broader approach where it is for the entire project/organization. Regardless such terms always have a negative impact. Just remember all the MakerWorld spam everywhere after they launched with high rewards.

How often do you lubricate the linear guides?

I am curious how often do you service the linear rails on the 3D-printer:

- How often do you lubricate them (MGN9 or MGN12)?

- How do you lubricate them?

- What volume of lube do you use?

Explanation of how often you should do it (HIWIN Lubricating instructions for linear guideways and ballscrews)

Most 3D-printer use MGN12. Reading the HIWIN documentation they shall be lubricated every 20-50km (depends on a lot of factors).

How much is 50km in print time? Assuming an average speed of 300mm/s that would be approx. 46 hours!

In other words, the generic MGN12H carriage needs 1-2 times per week maintenance.

How much lube is suggested (horizontal mounting)? 70µL for MGN12H. For MGN9H it is 30µL!

Nesting capabilities of slicer (overview)

Short overview of how good the nesting capabilities of various 3D slicer are.

The task is simple: placing as many of these shapes on a 200x300mm printed as possible. Manual (quick and dirty for reference): 6 pcs.

Ranking:

- Ultimaker Cura: 7 pcs.

- human (me): 6 pcs.

- Orca slicer: 5 pcs.

- PrusaSlicer & BCN3D stratos: 4 pcs. By switching (for this particular part) from the worst (Prusa) to the best (Cura) slicer the nesting performance improved by a whopping 75%!

Ultimaker Cura:

Prusa:

BCN3D Stratos (forked from an old version of Cura):

OrcaSlicer:

Print in place ratchet design

After half a dozen iterations, this was the first reasonably working, acceptable feeling, and good-sounding ratchet mechanism.

allows clockwise rotation blocks counterclockwise rotation

design features:

- allows for a large inner bore (e.g. rotary encoder shaft or 5.2mm screwdriver bit)

- printable with 0.4mm nozzle

- 2cm diameter

- no assembly required. Print in place.

To get a full ratchet: mirror the assembly and add a mechanism/part that pushes one of the springs out. In neutral both leavers are engaged and the ratchet is completely locked.

Btw. Good luck copying it without going through half a dozen of iterations. Going from it barely works to this isn't easy. For my part: Version 5 was working and close to the final design. It took another 10 rounds to get it usable and from there some more to fine-tune it.

Shape optimized spoolholder

Quick and dirty 5 minutes craft: Draw a rough shape, define the contact surfaces & load, click run, and get the optimized shape. The last step is converting the output to a printable shape and running one more simulation to double-check it is strong enough.

This particular holder is a filament spool holder designed to be loaded with up to 5.5kg of filament (1x2.5kg, 3x1kg).

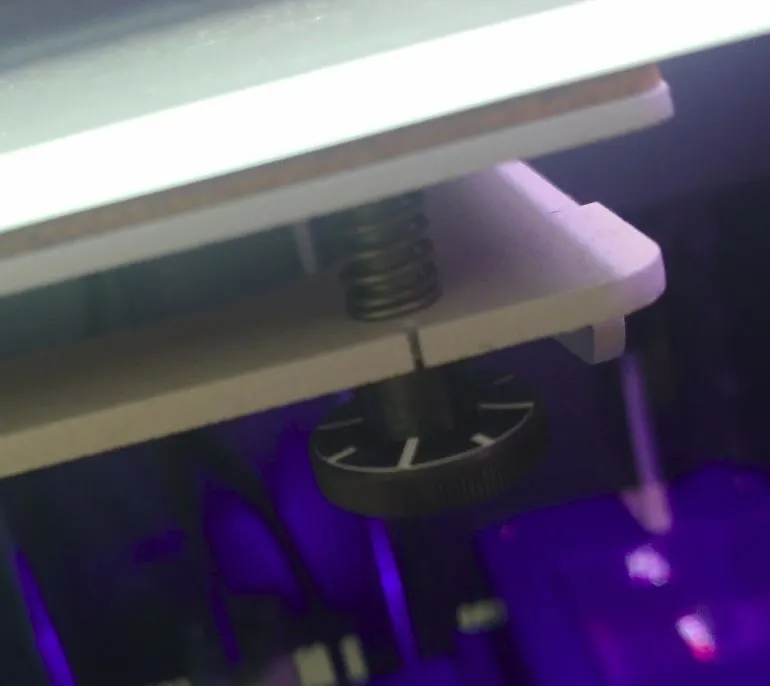

Why do 3D printer manufacturers not get the details right? e.g. rotation indicator on bed levelling wheels

Building a 3D printer is easy. Getting the details right to build a great 3D printer is hard, as this is where most companies fail. Why?

For example, on this printer, the bed is a three-point mount (two wheels for adjustment at the front of the printbed) and the printer's bed levelling dialogue doesn't show the height difference that needs to be adjusted (which most 3D printers do). It does show how much it needs to be turned, and the bed levelling wheels have 1/8th turn indicators, making it easy to get it perfect.

In short, instead of an arbitrary number like 0.3mm that has no meaning to the user, they tell the user to turn this knob 1/4 of a turn. An instruction the user can follow.

** Why is this so outstanding? It doesn't cost much, but it improves the user experience. Are companies blind to these improvements because the engineers are experienced, or is there a lack of testing during development?**

By the way, years ago I did such a fix/modification myself on a Tronxy XY2 pro by adding indicators on the wheel for 0.2mm height difference so I could convert the number to rotation: https://www.printables.com/model/301670-replacement-bed-leveling-wheel

For those venturing into 5-axis 3D printing and hybrid manufacturing, what is your tool chain?

With 3D printers like the Open-5x or tool changers (e.g. Prusa XL) both, 5-axis simultaneous 3D-printing as well as hybrid manufacturing (additive followed up by subtractive), is more accessible than they ever were.

For those already venturing into this endeavor: What is your toolchain/software?

Currently, I finish the additive/3D print before running a second gcode for the subtractive part (contact surfaces, threads, ...). This is far from an efficient and powerful process.

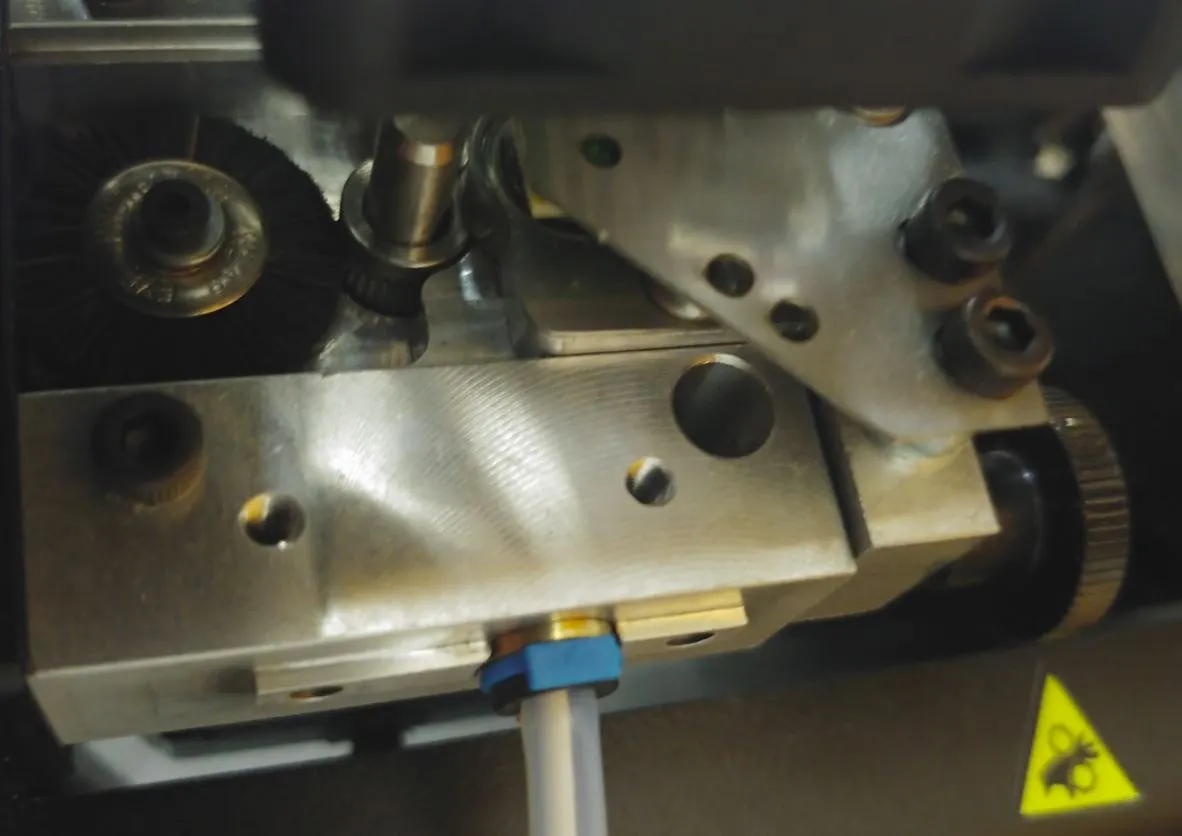

Extruder with a cleaning brush (industrial desktop 3D-printer)

The extruder of the 3Dgence P255 3d-printer features a brush to clean the extruder gear.

One of those permanent temporary fixes.

Needed as soon as possible a spool holder for larger spools so printing anything that is dozens of hours was out of the question.

Solution? Looked at the heavy shelves and had an idea.

One remix later, a 1-hour print and with some round wood that was lying around this spool holder was born.

I like the position of the spool so much that it is here to stay.

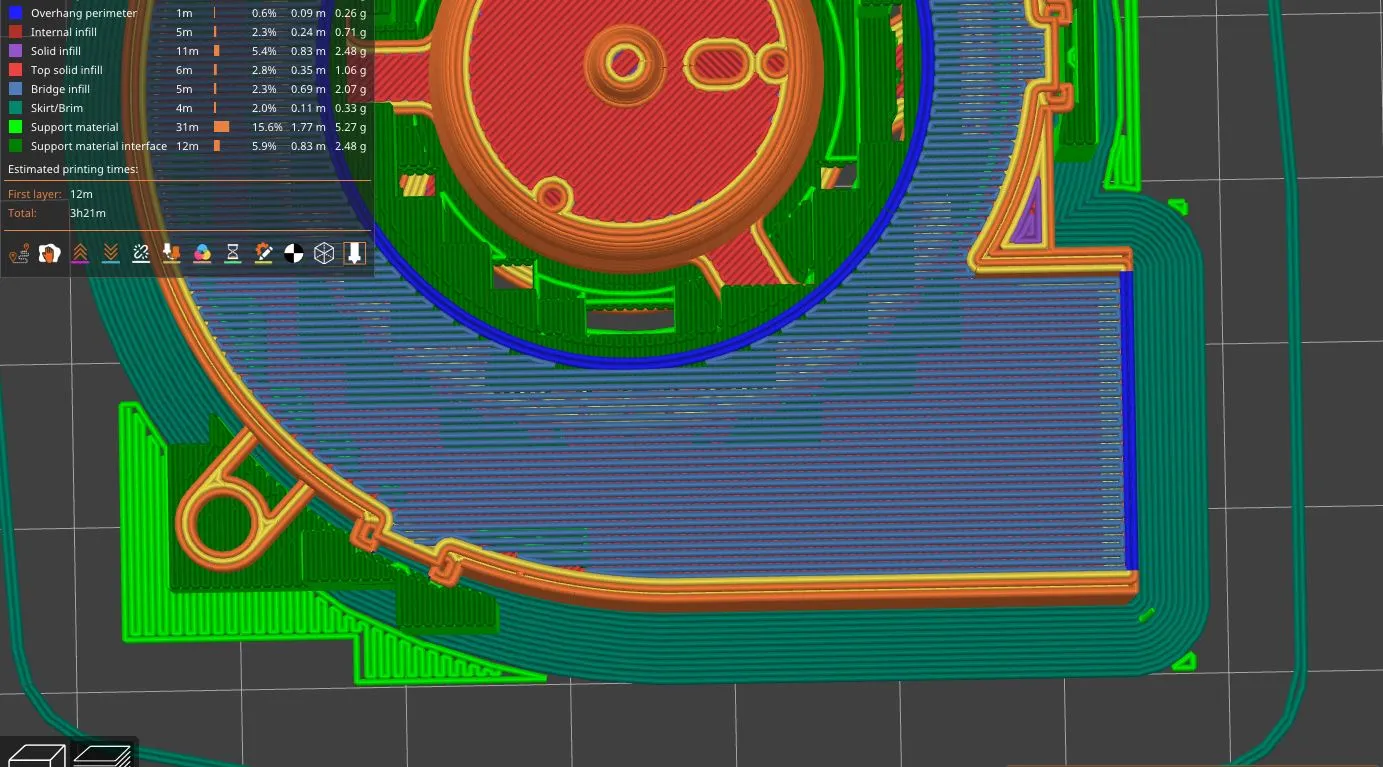

How do I fix this Prusaslicer output?

With this particular model, Prusaslicer is very optimistic about bridging and support generation:

- the right side (dark blue) has no support that could help with load-bearing

- the entire layer will be connected to those two lines

- more than 5cm long bridges

I don't think this gcode will successfully print.

How do fix adjust the cura setting to generate a printable output?

The model in question is: https://www.delta-fan.com/Download/3D/BUB0612HJ-00.stp

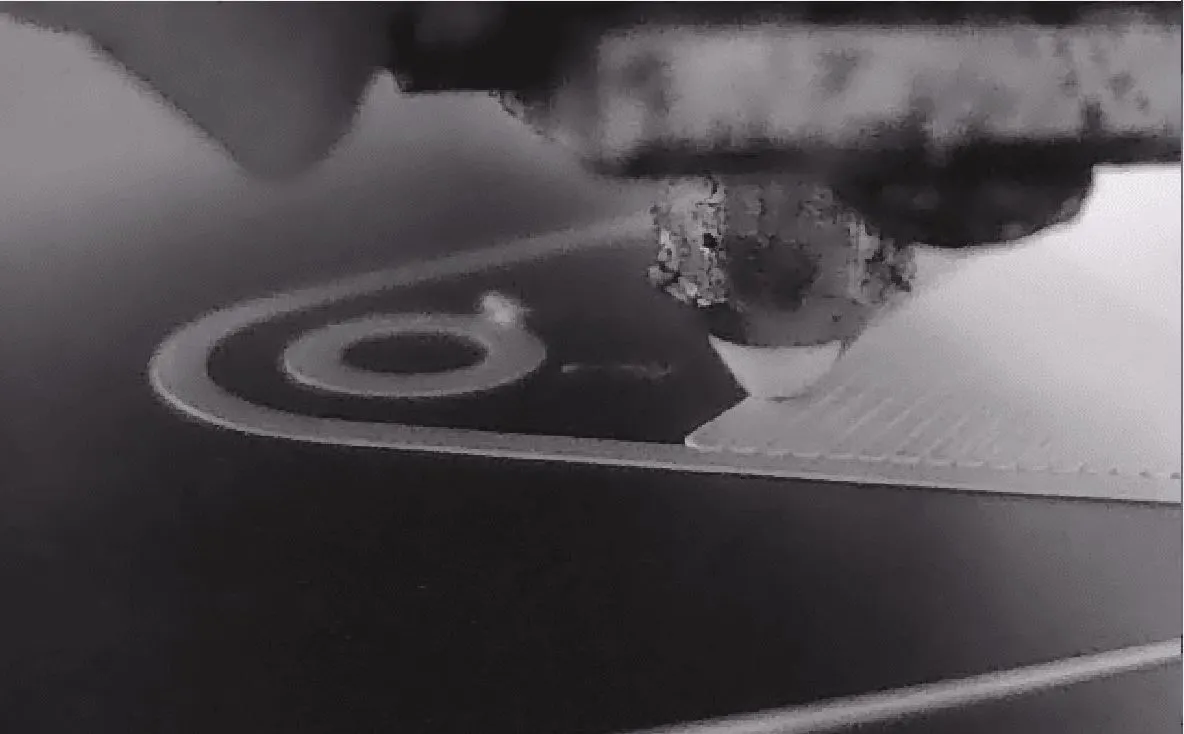

What is your favourite camera setup?

What cameras did you add to your 3D printer? What is your favorite camera angle?

For me, the nozzle cam watching the first layer is my personal favorite (OV9281 image sensor).

BambuLab recall: Should you replace the cable yourself? ft. EN 50678

As you might be aware BambuLab issued a recall for the BambuLab A1 3d-printer. In particular, the issue is the mains-voltage (230V AC) heat bed cable.

As a resolution, they offer two solutions:

- Ship the entire printer back to them and receive a replacement printer.

- They mail a new cable and you install it.

What BambuLab doesn't mention at all is the test according to EN 50678 (Verification of the effectiveness of protective measures of electrical equipment after repair). Unless you can perform this test I would recommend choosing the printer replacement.

Would you still buy a Prusa Mini+?

Right now looking into bang for the buck workhorses with a small footprint/build volume. A description that fit the Prusa mini+ perfectly in the past, but it feels like Prusa is a dinosaur that hasn’t moved with the times.

So who is still buying the Prusa mini+ and why?

Personally: While Prusa has outstanding support, good data protection, and does good things but there is now the Bambu Lab A1 mini.

Prusa mini is at the moment 500€ plus 20€ for a filament sensor (sic., it’s nearly 2024 and that’s an paid upgrade on half a grand printer) and another 7€ for WiFi.

Bambu Lab on the other hand is 320€.

Looking at the specifications, the A1 looks like a clear winner: For maintenance, there are three tasks: 1. cleaning and lubricating the mechanics (both are the same in this respect); 2. cleaning the build surface (both are the same); 3. maintaining the hotend and here Bambu Lab is clearly the better system as you can replace the nozzle in just a few seconds compared to Prusa’s E3D v6 hotend, which requires hot tightening.

The operation is not that different. Both support network, web interface, and automatic bed leveling probed at the nozzle. Bambu Lab has a camera built in, but this requires the printer to be connected to the BambuLab cloud, which may not be possible as the model data is shared with/uploaded to China. I would say this is still a strong point for Prusa as privacy is not an issue with their printers which means they can be easily deployed.

Performance should be close with input shaping enabled, but the A1 mini has the higher flow rate hotend, which means BambuLab is once again the winner (still no highflow at only 28 mm^3/s but twice the flow of a Prusa V6).

The build volume is identical and the footprint is also almost identical, so again no point where Prusa beats BambuLab.

Value? I have already mentioned it. 1.6 Bambulab for the price of 1 Prusa is a clear answer. If Prusa still had the 400€ original launch price and a filament runout sensor included, maybe the answer would be Prusa due to privacy/easier integration. The 200€/printer price difference is so significant that I don’t see who is still buying multiple Prusa mini+.

Btw. is there another printer on the market that just works paired with a small footprint and excellent value?

Your though on E3D Revo Roto extruder?

Today E3D launched their latest extruder. What's your thought on the Revo roto?

only/first Reviews: Made with layers (formally Thomas Sanladerer): https://www.youtube.com/watch?v=X5UpN0QaxGY E3D launch video: https://www.youtube.com/watch?v=W6GxPZUM0k4 product page: https://e3d-online.com/products/roto-extruder

155 GBP (without tax) for the sensor version. Equipped with a normal brass nozzle and a low-power heater core.

The pushing force isn't great as it can't do more than 6mm/s (14mm^3/s, approx. 60g/hour) limiting it to 0.15, 0.25 and 0.4mm nozzles. That's significantly short of the E3D Hemera XS Revo performance they claimed this extruder matches.

Is 14mm^3/s enough for 200 USD+ extruder for 2024 and beyond if you could trade approx. 20g more weight for 4x the max. flowrate?

The beauty of 3D-printing: Just download the physical object.

3D-model collections like Printables or Thingiverse are awesome. Required (ASAP) a CPU socket cover to ship the motherboard. Found it online and 15 minutes later I had the part on hand.