-

Acetone is your friend

You might recall that I tried printing this fake lens last week and found it quite challenging.

So today for S&G, I figured I'd try to print it in two halves like so:

Then instead of gluing or epoxying them, I joined them with acetone: it's quite a thin profile, so it's a good test of the strength of the bond.

Well, I let it cure for half an hour just to make sure all the acetone inside the bond had evaporated, and it certainly is plenty strong! Strong enough to take a vigorous chemical polishing - with acetone also - while applying a fair amount of pressure and stay in one piece.

I polished it by hand for 5 minutes and it's even a bit lens-y now 🙂

I'll let it cure for another 24 hours for good measure, then tomorrow I'll mount it in the lathe and I'll polish it some more with acetone, to see how clear I can make it.

It's never going to be any good of course, but it's interesting to see how much it can be improved, if only to find out what I can do with PLA.

-

Weird extrusions

I just stopped a failing print and noticed some weird extrusions happening (not english native speaker, also I'm a 3d printing noob, don't know whether that's the right word). You can see it in the image. Any tips to improve printing quality?

I'm printing on an Ender 3 V3 SE. This print was with standard settings.

EDIT: as a clarification, this isn't why I stopped the print. It failed to adhere to the print plate at some spots. Redid my z offset and hopefully that solved it.

-

Help: X-Mas inspiration needed

Like every year I am absolutely clueless what to gift my loved ones (and of course always too late getting/creating them).

Thats why I'm asking you guys, for inspiration - what, if any, are you printing this year as gifts for your loved ones?

-

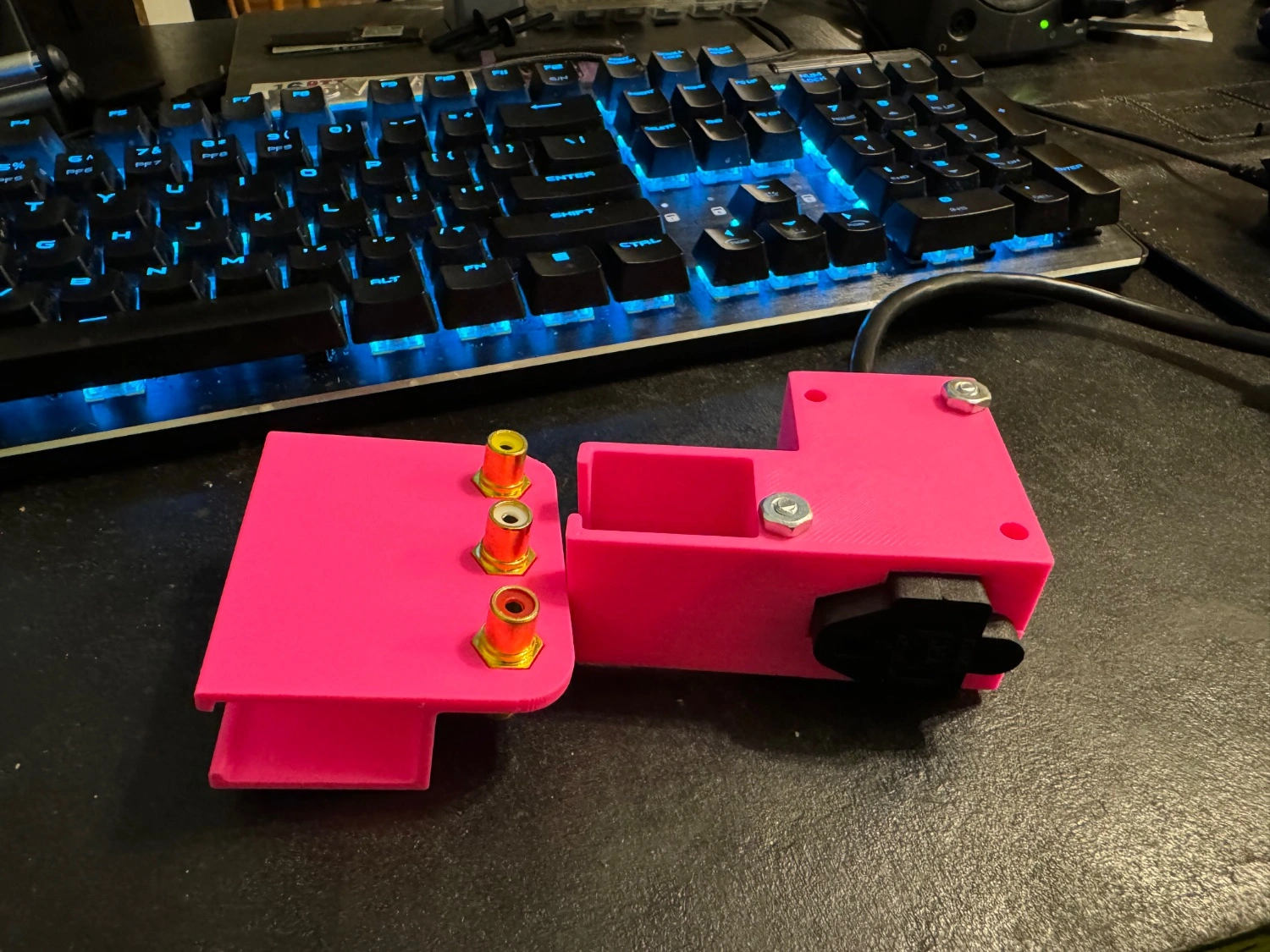

Experience with Orbiter 2.0 extruder

I'm currently using an Orbiter 1.5 and it's pretty decent but I'm looking for an upgrade. I like the light style extruder sitting on the gantry over a Bowden system as it allows for flexible filament and has much better control over retraction.

Is the 2.0 a significant improvement over the 1.5? Should I get a new hotend as well with it?

Right now I'm using a MicroSwiss all metal hotend and am quite satisfied with it.

Print speed is okay I guess.

-

Is your 3D printer insulated? How is the print chamber heated?

How is the build chamber in your 3D-printer heated? Is there any thermal insulation and if how thick is it?

My two cents:

** thermal insulation**

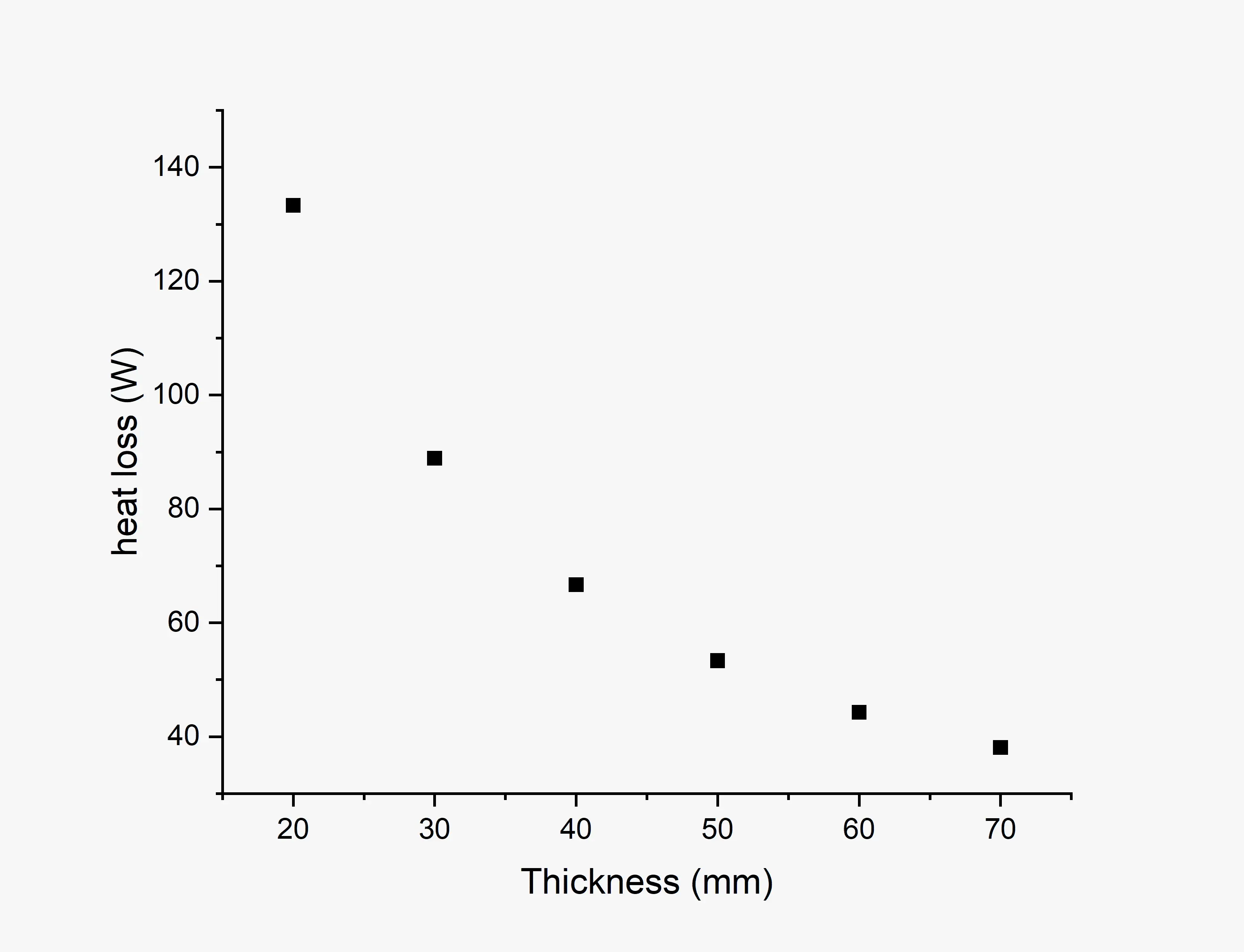

That's the math for a small 300x300mm printer heated to 70°C (for 130°C tripple this number).

With a 6030 aluminium extrusion a 60mm insulation would fit within the walls and bring down the heatloss to approx. 45W. In other words: Once it is heated up the thermal losses are small enough for it to hold the temperature on its own. Reducing the overall power consumption.

heating/temperature control

For cooling and heating: oil<-> air heat exchanger/radiator might be a good solution:

- place one inside the printer

- the other on the outside

- insert a heater in the loop (only when heating is required, for cooling keep it off)

- possible to push past the 100°C liquid temperature.

Add a fan that circulates the air within the chamber to equalize the temperature.

This way the chamber can be heated and cooled without venting any air into the room.

-

Trouble with warping

I have some very consistent issues with warping when printing ASA/ABS, which is really annoying since I'm trying to print my voron parts. It's not warping massively, but enough to mess things up.

I print with these general settings, on a textured PEI flex-plate.

- heated chamber @ 45-47C (can't go much higher)

- bed temp @105C

- first layer 255C, other layers 245C

- fan off, unless it's an overhang >=50% or layer time is <10s. Fan maxes out @70% unless bridging.

- speed 200/120 mm/s inner/outer walls

- first layer 50mm/s, 80mm/s infill

I've tried both with my regular Z-offset which creates a good uniform first layer, and slightly lower to kind of push it more on to the plate (but worse looking)

- I've cleaned the plate with pure IPA

- I've tried glue stick

- I've tried brim both skirts/mouse ears, which help but don't eliminate it. (5mm, 0.15mm space)

ABS seems to be a little easier to print than the ASA. I'm using filament from Polymaker

-

Wife wanted a Apple Pencil Case, so I made one

It’s a slight modification to my existing design which can be found here: https://www.printables.com/model/261466-apple-pencil-gen-1-case-mkii

The two tone was originally created by accident as we were running out of light blue and I decided to go all out on the top side.

She is very happy with the results.

-

Phone dock with ikea wireless charger

See https://imgur.com/a/zMvfpRc for more pics

A few months ago, Scott Yu showcased a phone dock inspired by Dieter Rams' iconic DN40 digital clock.

That got me inspired to create my own version, featuring a wireless charger from IKEA. The charger is integrated into a panel that slides into a slot within the dock's body. Before assembling, the cable is routed through a hole in the back for a clean and functional setup.

Printed with Prusament PLA Galaxy Black & Prusament PETG Orange.

To top it off, I even developed my own Android docking app — because, why not? :D

-

Shitty first layer on "big" parts, need some help

I have a cheap bedslinger, an Anycubic Kobra 2, and generally it's a pretty decent printer at the price. I have flashed klipper FW on it, so I'm not using Anycubics FW.

I have issues whenever I try printing bigger parts, the first layer is always complete shit (see post photo).

Heightmap, measured with inductive probe !heightmap range is only 0.085mm from min to max, so it should be reasonably flat. The heightmap is automatically recalibrated and loaded as part of my print_begin macro.

Slicer settings for line width !slicer settings for layer widths

I don't know if my printer just doesn't correct Z-height during first layer, if my line width settings are completely messed up or what is causing this, but the issue is only apparent on bigger parts with large contract surface on the bed.

[SOLVED] It was just Z-offset that was too low causing this. however when running the calibration routine from ellis3dp on first layer squish, the settings that looked good on the small calibration patches, looked like crap on bigger prints. I needed a bit higher Z-offset, but that solved it.

-

Sneaky Joe Miniature Tutorial

YouTube Video

Click to view this content.

This is a long video about printing and cleaning up FDM minis. Great video if you are hyper fixated on this topic. I'm doing a test print now, using his support profile and Fat Dragon's .08 profile for the A1 Mini. Tons of good information.

-

Model archiving and organization?

Bit of a weird question but how do you store and organize your models/STL files?

I do most of my CAD in OnShape these days so I have The Cloud for all the convenience and future horror of that. And... when I grab stuff from one of the sites like thingiverse... I SHOULD save the model but I don't and it has only bothered me once when I lost my webcam cover. And I probably spent more time searching for a replacement than it took to just make my own.

But I want to get more into kickstarters (... I feel dirty) and buying cool models and those I DO want to archive and save.

Most likely I'll just make a folder structure and sync it to my NAS with syncthing. But are there any better/more elaborate solutions? One of those "have server, will spin up container" things but figured I would ask first.

Thanks.

-

Proposal to reduce or completely eliminate waste from filament swaps with multicolor or multi-material printing: “purge to filament”

It occurred to me that one way to potentially eliminate all filament swap waste from purge towers or Bambu-style filament “poops” is to instead do something similar to a “purge object” or a “wipe object” but where the object is… filament.

The idea was somewhat inspired by Stefan’s video from a few months ago, which first introduced me to the idea of printing filament: https://m.youtube.com/watch?v=CQ-N1fr4N0w

If the purge object is new filament, then you don’t need to figure out what to use it for immediately; you can store the mixed-color filament for later use until you have a genuine need for a color-agnostic or structural object. No more piles of fidget spinners you didn’t really want.

A few other thoughts:

- The filament probably needs a minimum bend radius so it can feed into an extruder without breaking. One option would be to print a circle or a rounded square / squircle type of shape toward the perimeter of the build volume (potentially multiple concentric ones, or spiralized shapes). Another option would be to print disconnected straight segments.

- The filament doesn’t need to be printed flat. It could potentially spiral upwards (likely with supports). That could help avoid print head collisions for taller models (in which case you might not want the head to have to get back down to <1.75mm from the print bed). In the most general case, the filament could be printed at arbitrary angles, even vertically, and could start at some height above the build plate (potentially supported by the object itself, for example in an object where color changes don’t start at the very bottom). Maybe the angle could even be optimized to provide the best match between purge volume per layer and volume of new filament printed on each layer.

- A good solution probably requires a good way to connect multiple segments of printed filament together

- Mixing materials rather than just colors seems like a bad idea to me (e.g. soluble supports) but I’m going to mention it as a possibility anyway; you could conceive of something inspired by Stefan’s composite material and intelligently organize the different materials within your new filament.

- You could potentially control the mixes / transition colors that go into your purge filament, or even choose multiple different new filaments for different color transitions. For example, you might have separate new filaments for red-green, green-blue, and blue-red transitions. Maybe you want it create particularly pretty new filament, or avoid particularly ugly combinations.

I don’t actually have a multi-color / multi-filament printer, and I don’t have time to experiment with this (even though the first prototype could be as trivial using a filament shape as the wipe object in PrusaSlicer). I’m mostly sharing this to establish prior art in case someone nefarious seeks to patent something similar in the future (which is also why I added some half-baked thoughts that might make other things become obvious to someone skilled in the art), though it’d be great if the idea is actually good and someone could implement it well. Or for all I know this does already exist.

Thanks for taking the time to read this! Feel free to repost/share/steal the idea if you like it.

-

Sigh, why do people use these hygrometers?

These have to be the least accurate things I have ever seen.

The rectangular one is accurate or accurate enough and has been what I used but I noticed files all had cutouts for these round hygrometers...

Well from my 6 pack 1 is within a margin of error to even be useful.

I get they aren't expensive but seems like a waste of money for this bad.

-

Resources to learn FreeCAD

Back in college, I had a few classes on CAD (mostly for engineering design), and I became decently proficient with CATIA, SolidWorks, and Autodesk Inventor. Now that I’m getting into 3D printing, I’m coming back to CAD and finding my skills pretty rusty.

I plan to use FreeCAD as my main tool. Could anyone please recommend some tutorials that I can complete that would give me a solid working knowledge of FreeCAD and help me brush up on CAD in general?

-

Thermometers reading different temperatures on cold printer?

I am in the process of buttoning up a Nitehawk conversion on my Voron. I also replaced my extruder thermistor with an OE replacement purchased from a reputable vendor.

Post setup, my heated bed is reading spot on (it's 18.3 C in my basement aka 65 F). I verified that my extruder is also at ambient temperature by wedging a Thermapen under its silicone sock and letting it acclimate for 10 minutes. The I'm not sure why the extruder would be reading high.

I bought a spare thermistor and wired it in. The result was identical.

Thoughts? Ideas? I'm pretty sure I have the Nitehawk and thermistor set up correctly.

[extruder] step_pin: nhk:gpio23 dir_pin: nhk:gpio24 enable_pin: !nhk:gpio25 heater_pin: nhk:gpio9 sensor_pin: nhk:gpio29 pullup_resistor: 2200 sensor_type: ATC Semitec 104NT-4-R025H42G`

-

FreeCAD v1.0 released.

blog.freecad.org FreeCAD Version 1.0 ReleasedAfter more than twenty years of intense and sustained development, the FreeCAD community is proud to announce the release of version 1.0. FreeCAD 1.0 is now available for download on all platforms.…

cross-posted from: https://lemmy.world/post/22260935

> Let's take her out for a spin...

-

With Core ONE, Prusa's Open Source Hardware Dream Quietly Dies | Hackaday

hackaday.com With Core ONE, Prusa’s Open Source Hardware Dream Quietly DiesYesterday, Prusa Research officially unveiled their next printer, the Core ONE. Going over the features and capabilities of this new machine, it’s clear that Prusa has kept a close eye on the…

Sad to see them go this way, but not unexpected, thanks to the article by Josef Prusa where he complains about open source.

-

Any recommendations for a low-cost, low-hassle printer?

Several years ago I leapt enthusiastically into the realm of 3D printing by buying a massive, expensive delta-type printer. I had to put it together myself, which was fun, but after that I struggled to get it to print well. Even simply trying to get the prints to stick to the bed were difficult, leading me to add huge brims to all my parts which were a pain to cut off afterward. Eventually I gave up fiddling with it and it’s been gathering dust ever since.

I know that a lot of you treat the hobby as an opportunity for endless tinkering and optimization, which is great, but I think I’ve realized that what I’d prefer is something that just works out of the box with a minimum of adjustment.

-

Help me identify a filament's material

I found a small length of filament in the parts bin. I don't know what it is, and nobody else here does, or remembers ordering it. I'm pretty sure it's a sample that was sent by Prusa when we ordered the printer, and it's probably not a special material.

It's feels "gummy" and a lot softer than PLA, but not really rubbery either. And I tried printing something with it at 230C as if it was PLA and it's clearly not hot enough: it's able to flow out of the nozzle but it barely sticks to the bed.

Any idea what it could be?